Fricks has a line-up of award-winning industrial concrete floors, all built with superior workmanship for outstanding customer satisfaction. Fricks is the recognized leader in premium floor construction, and shrinkage compensating technologies. Let a Fricks representative show you how we can design your facility to maximize durability in those areas that need it most while providing award-winning flatness products, hygienic epoxy surfaces, or optimized paving solutions to other areas.

Fricks establishes value early with optimized designs that fit your needs and budget. We do all our own installation, construction and testing with our equiment and our people. Upon completion, Fricks warranties your product. Fricks is the ONLY design/build concrete floor company you'll ever need.

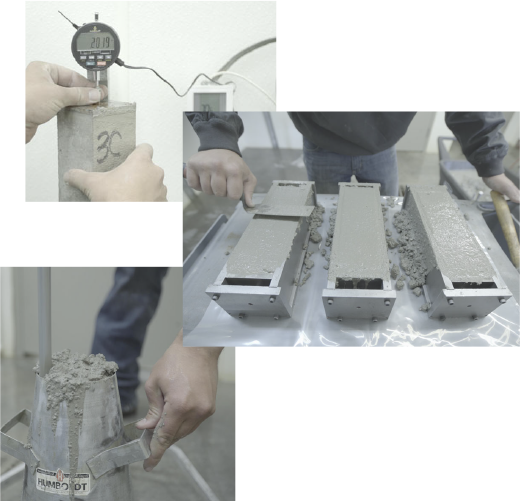

FRICKS-TESTED - Fricks has it’s own inhouse testing/lab facility.

FRICKS-DESIGNED - Designed with maximum optimization, comprehensivetesting and integrated performance.

FRICKS-STAMPED - Engineered, designed and nationally stamped.

MOBILIZED - Fricks mobilizes our own trained employees and equipment.

SINGLE SOURCE - Total accountability, cost control and performance.

WARRANTIED - Fricks stands behind the entire floor system.

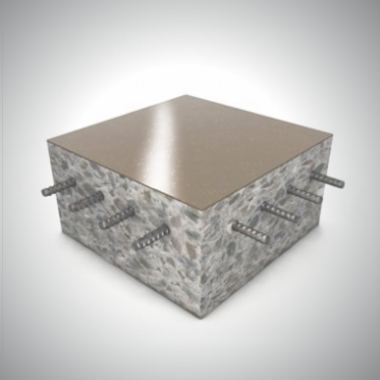

Behind every Durable Fricks Floor is a dependable system of joints and detail work designed to withstand the abuse of forklift traffic. Construction joints are flat and Durable reducing equipment maintenance and repair cost. Fricks attention to detail ensures that construction and control joints activate and perform properly, reducing the potential for cracking on even the smallest of details and enables us to deliver the most Durable joints in the world.

Behind every Durable Fricks Floor is a dependable system of joints and detail work designed to withstand the abuse of forklift traffic. Construction joints are flat and Durable reducing equipment maintenance and repair cost. Fricks attention to detail ensures that construction and control joints activate and perform properly, reducing the potential for cracking on even the smallest of details and enables us to deliver the most Durable joints in the world.

CONSTRUCTION JOINT DOWELS - The most innovative technology used to provide the greatest load transfer across construction joints and allow horizontal slab shrinkage movement in all directions.

EXISTING TO NEW SLAB TRANSITION - Transition from existing facility slabs to new slabs is very important to provide facility cohesion and can be made extremely Durable with the proper attention to details and techniques.

CONTROL JOINT DOWEL - Control joints lose aggregate interlock once the joints activate requiring the need for proper load transfer devices.

CONSTRUCTION JOINT DOWEL - Construction joints exposed to forklift traffic protected with steel angles or flat plate bars to provide the highest level of durability and impact resistance for the most demanding forklift traffic patterns.

Fricks is meticulous when it comes to testing our product to ensure reliable results prior to and during the construction process. Fricks tests every area of the construction process from the material to the subgrade and expansion properties.

Most contractors don’t make adjustments in extreme temperatures, but excessive heat or cold during the construction process can have damaging affects, poor performance and greater crack potential.

Fricks superior floor systems are an investment that needs to be protected and Fricks takes great care in adjusting their construction processes in climate extremes to ensure long-term quality and performance.

Most contractors don’t make adjustments in extreme temperatures, but excessive heat or cold during the construction process can have damaging affects, poor performance and greater crack potential.

Fricks superior floor systems are an investment that needs to be protected and Fricks takes great care in adjusting their construction processes in climate extremes to ensure long-term quality and performance.

Concerns with Construction in COLD TEMPERATURES

The FRICKS SCC Advantage Floor is a superior floor system and an investment that needs to be protected. Excessively cold temperatures can have damaging affects resulting in greater crack potential, possible curling and wider construction joints. When temperatures drop toward 32o, costs to address low temperatures can rise.

- Accelerated and increased slump loss

- Increased rate of setting resulting in greater difficulty with placing and finishing

- Severe cold joints that result in greater crack potential

- Decreased durability

- Early freezing can result in a reduction of up to 50 percent in the ultimate strength.

- Ice formation results in the disruption of the cement paste matrix causing an irreparable loss in strength.

- Increased crack potential caused by excessive shrinkage and thermal stresses

- Decreased surface abrasion resistance

- Greater variability of surface appearance and aesthetics

How Fricks adjusts for COLD TEMPERATURES:

- Sprinkling the concrete aggregate piles when possible or as much as possible

- Reducing the mix time

- Protecting the concrete from rapid moisture loss during finishing by blocking wind, wind tunnels and sun. In some cases potentially using foggers in extreme conditions

- Minimizing transport time. (ensuring un-obstructed access to the point of placement)

Concerns with Construction in HOT TEMPERATURES

Hot weather can create problems in mixing, placing, and curing hydraulic-cement concrete that adversely affect the properties and serviceability of the concrete – due to the increased rate of cement hydration and increased evaporation rate. When the concrete temperature increases over 90o the following effects increase exponentially:

- Increased water demand

- Increased W/C Ratio

- Accelerated and increased slump loss

- Increased rate of setting resulting in greater difficulty with placing and finishing

- Decreased durability

- Lower strength caused by the rapid setting and higher water demand

- Increased crack potential caused by excessive shrinkage and thermal stresses

- Decreased surface abrasion resistance

- Greater variability of surface appearance and aesthetics

How Fricks adjusts for HOT TEMPERATURES:

- Sprinkling the concrete aggregate piles when possible or as much as possible

- Reducing the mix time from 90 to 60 minutes

- Proper crew staffing

- Starting early and working towards pouring out before the sun rises.

- Decreasing placement size when applicable

- Reducing the width of the placements when possible

- Protecting the concrete from rapid moisture loss during finishing by blocking wind, wind tunnels and sun. In some cases potentially using foggers in extreme conditions

- Minimizing transport time. (ensuring un-obstructed access to the point of placement)

Download our Hot Temperature Concrete Construction Brochure »

Greener Solutions

Fricks is committed to establishing greener solutions with processes that reduce the carbon footprint of the projects we build. We utilize natural resources whenever possible like our monolithic traprock, by utilizing less concrete and avoiding chemicals in the construction process. In addition the durable self-polishing floor provides an end result that requires fewer cleaners.

Fricks is a member of US Green Building Council and Green Advantage and continues to be a leader in environmentally-friendly design build.

Cost Savings over the life of the facility; Operating Equipment Savings; Up to 90% Fewer Joints; Greater Durability

Cost Savings over the life of the facility; Operating Equipment Savings; Up to 90% Fewer Joints; Greater Durability

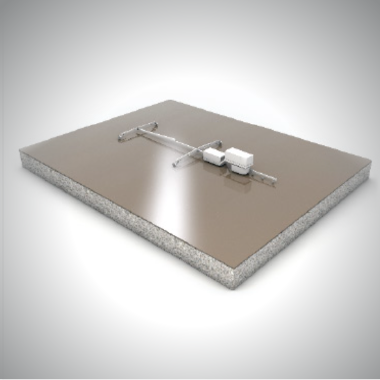

Our Most Durable concrete floor for the Most Demanding facilities.

Our Most Durable concrete floor for the Most Demanding facilities.

An Impermeable Traprock Shell to improve performance and durability.

An Impermeable Traprock Shell to improve performance and durability.

Award-winning Flatness and Durability that has proven to be the industry's best floor.

Award-winning Flatness and Durability that has proven to be the industry's best floor.

FPS Automatic Storage Retrieval System floors built thicker and stronger.

FPS Automatic Storage Retrieval System floors built thicker and stronger.

Our conventional floor with Fricks’ Finishing Techniques for unmatched durability.

Our conventional floor with Fricks’ Finishing Techniques for unmatched durability.

Introducing Fricks Optimized Paving providing impact resistance, reduced curling and shrinkage at lower costs.

Introducing Fricks Optimized Paving providing impact resistance, reduced curling and shrinkage at lower costs.

Fricks Concrete Wall Curbs are built with the same high quality as our legendary floors.

Fricks Concrete Wall Curbs are built with the same high quality as our legendary floors.

Fricks Automated Material Handling concrete floor solutions for productivity.

Fricks Automated Material Handling concrete floor solutions for productivity.

Modern warehouse design and automation delivers increased revenue and decreased costs.

Modern warehouse design and automation delivers increased revenue and decreased costs.

Fricks provides a variety of topping product appropriate for the needs and use of your facility.

Fricks provides a variety of topping product appropriate for the needs and use of your facility.